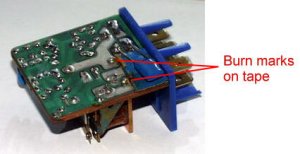

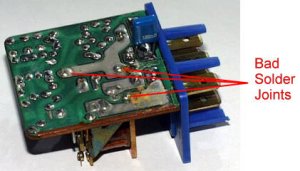

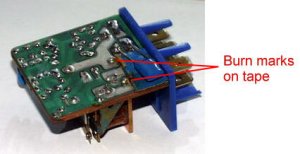

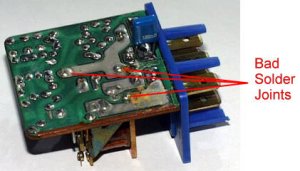

| Many

Bricksters have experienced no-start problems that were

later traced to the fuel pump relay unit. On closer

inspection, it was often discovered that the source of

the problem was bad solder joints inside the unit where

the the actual electromagnetic relay is soldered to the

circuit board. The bad joints would work for many years,

but would eventually get very hot because of their

increased resistance. This heat would often show up as

burn marks on the circuit board or on the relay, and in

extreme cases would discolor or melt the plastic casing

of the unit. In many cases

the bad solder joints can simply be resoldered. Even if

you do decide to replace the unit rather than repairing

it, resoldering the joints of the old one will often

yield a perfectly usable spare.

Description Description

The fuel pump relay unit on

1978-on (or so) K-jetronic-equipped 240s is actually more

than just a simple relay. It also contains a circuit that

listens to the ignition system to determine whether the

engine is running. When the unit detects an ignition

signal, it switches the fuel pump on. When the ignition

signal stops, it switches the pump off.

Locating the Fuel Pump Relay

Unit

The fuel pump relay unit is

located under the dashboard in the vicinity of the

steering column. I have found them clipped to the

crossmember where the steering column mounts; and I have

also found them mounted higher up between the instrument

cluster and the firewall. The unit is usually either

black or mustard yellow and has a six-blade connector on

one end.

Opening the Unit

After locating and removing the

relay unit, pop open the plastic casing by prying the

case apart so that the end with the connector slides past

the retaining wedges. This is a little bit difficult, but

can be done without damaging the unit.

Inspecting the unit

Once you've got the unit open,

the first thing to do is check for a faint burnt odor.

This would indicate whether or not it's gotten too hot in

there.

Next, check for burn marks that

would indicate excessive resistance. You'll usually find

them on the circuit board near the offending connections

or components.

Next, put your thumb on the big

relay on the circuit board and try to wiggle it. If the

big part of the relay (not the small hinged part) wiggles

at all, its solder joints are bad and must be

re-soldered.

Check

the contact points between the hinged and stationary part

of the relay. It's hard to say how much pitting or

discoloration is normal, but all of them that I've looked

at (including the perfectly good ones) have had a little

pitting. If they're really bad, you may be able to extend

their life by sanding them, but's impossible to say how

much Check

the contact points between the hinged and stationary part

of the relay. It's hard to say how much pitting or

discoloration is normal, but all of them that I've looked

at (including the perfectly good ones) have had a little

pitting. If they're really bad, you may be able to extend

their life by sanding them, but's impossible to say how

much

On the solder-side of the cicuit

board, check that all of the solder joints are smooth and

shiny. A Dull or crinkly appearance indicates poor

soldering.

|

Description

Description

Check

the contact points between the hinged and stationary part

of the relay. It's hard to say how much pitting or

discoloration is normal, but all of them that I've looked

at (including the perfectly good ones) have had a little

pitting. If they're really bad, you may be able to extend

their life by sanding them, but's impossible to say how

much

Check

the contact points between the hinged and stationary part

of the relay. It's hard to say how much pitting or

discoloration is normal, but all of them that I've looked

at (including the perfectly good ones) have had a little

pitting. If they're really bad, you may be able to extend

their life by sanding them, but's impossible to say how

much